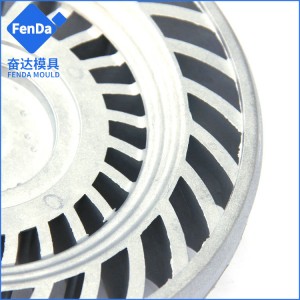

I-OEM Aluminium Alloy LED Street Light Die Casting Housing Die Cast Products

I-Fenda Aluminium Alloy Die Casting & CNC

| Inqubo

| Umdwebo namasampuli→Ukwenza isikhunta→ Ukusakaza ifa → Ukukhipha imali → Ukubhoboza nokuhlanganisa → I-CNC Machining → Ukupholisha → Ukwelashwa kwendawo → Umhlangano → Ukuhlolwa kwekhwalithi → Ukupakisha →Ukuthumela |

| Izisetshenziswa | Igumbi elibandayo elinezingqimba imishini yokuphonsa yokufa engu-400T--2000T.Izikhungo ze-CNC, i-EDM, i-WEDM, umshini wokushisela we-high-precision friction, umshini wokugaya i-CNC, umshini wokubhoboza we-CNC, umshini wokujika we-CNC, umshini wokugaya we-CNC, I-CMM, i-spectrometer ye-Oxford-Hitachi, isihloli sokuqina kwegesi |

| Okubalulekile | I-aluminium alloy ADC12, A360, A380, AlSi12(Cu), AlSi9Cu3(Fe), AlSi10Mg njalonjalo. |

| Ubuso | Ukuphungula,Ukususa,Ukupholisha,Ukudubula,Ukuqhumisa isihlabathi,Ukupenda,Imboza |

| Usizo Lwesofthiwe | Umsebenzi we-Pro-e/Solid/UG/Auto CAD/CATIA |

| Isicelo somkhiqizo | Imboni Yezimoto, Ukukhanyisa kwe-LED, Ezokuxhumana, Imishini Yendwangu, Ifenisha, Ithuluzi lamandla, nezinye izimboni zemishini. |

I-Fenda Aluminium Die Casting Advantage

1.I-Mold Design kanye Nokukhiqiza endlini

Isitolo samathuluzi sasendlini sisivumela ukuthi senze ukwakheka kwesikhunta se-die-casting, i-mold Fabrication & nokugcinwa kwesikhunta endaweni yokusebenzela efanayo.

Onjiniyela bethu besikhunta bazobuyekeza imidwebo yakho futhi baphakamise iziphakamiso ngokuhlaziywa kokugeleza kwesikhunta, okungakusiza ugweme izinkinga ezingaba khona noma izingozi ezingase zenzeke ekukhiqizeni kamuva.

2.Ikhono Lokufakela

I-Fenda ingumkhiqizi ochwepheshile onekhono lokukhulisa uhla lokufa, ngemishini yokukhipha ukufa engamathani angama-400-2000 wamathani ahlukene.Isithando somlilo esizimele somshini ngamunye we-die casting sisenza sikwazi ukuhlinzeka ngezinhlobonhlobo ze-aluminium ukuze sihlangabezane nezidingo eziyingqayizivele zamakhasimende.

3.ISO Certified kanye ne-IATF 16949 Certified

I-Fenda iyinkampani eqinisekisiwe ye-ISO 9001 futhi i-IATF16949:2016 inkampani yokukhiqiza eqinisekisiwe.Siqinisekisa ukuthi uthola izingxenye zezimoto zekhwalithi ephezulu kungakhathaliseki ukuthi idizayini iyinkimbinkimbi.Ngaphezu kwalokho, siqinisekisa ukuthi sithuthukisa imikhiqizo yakho sisebenzisa izinqubo ezingcono kakhulu ezaziwa emhlabeni wonke nokuthi ihlangabezana nazo zonke izindinganiso ezidingekayo.

4.CNC Machining Amandla

Sinikeza izinsiza zemishini ze-CNC ezingochwepheshe zezinto ezahlukahlukene kanye nezingxenye eziyinkimbinkimbi.Siqinisekisa ukunemba okuphezulu ku-prototyping esheshayo kanye nokukhiqizwa kwevolumu ephansi.

5.Ikhono Lokwelapha Okungaphezulu

I-Fenda ingakwazi ukuqedela ukwelashwa kwendawo ebonakalayo kanye nokwelapha ngokufafaza ngempushana njengokuqhunyiswa kwesibhamu, isihlabathi esihle, ukumboza ngempushana nokunye.Ngaso leso sikhathi, i-Fenda ibilokhu ibambe iqhaza ngokujulile ochungechungeni lokuhlinzekwa kwendawo iminyaka engaphezu kwe-17, ihlanganisa ngamasu abahlinzeki bemithi yokwelapha amakhemikhali amaningi, futhi ngokuphathwa kwamaketanga ayinkimbinkimbi, ukunikeza amakhasimende ukwelashwa okungaphezulu njengokufafaza ngepulasitiki, ukudweba, i-anodizing, i-electrophoresis, i-chrome plating, njll.

6. Uhlelo Lokuhlola Ikhwalithi

I-Fenda inaka ngokukhethekile ukulawulwa kwekhwalithi yenqubo yokukhiqiza ngobuningi futhi isungule inqubo yokuhlola ikhwalithi ephelele kanye nesistimu.Yonke imikhiqizo ihlolwe ngokuphelele noma yakhiwe ngokuhambisana namazinga.Imishini yokuhlola ihlanganisa: i-spectrometer, umshini wokuhlola owelula, i-CMM-coordinate, i-pass-stop gauge, i-parallel gauge, ama-caliper ahlukahlukene, njll., ukufeza ikhono lokulawula lesistimu yekhwalithi.